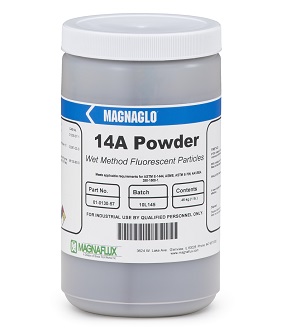

Product Description

![]()

Wet Method Fluorescent Magnetic Particles

14A is a highly sensitive fluorescent magnetic particle powder for locating very fine discontinuities in critical applications. Can be mixed with an oil or water for wet fluorescent particle bath inspection systems. The liquid mixture of 14A is sprayed onto a part during magnetization. It is used to detect cracks and seams, as well as inclusions, laps, tears and flakes. Flaws detected by this process can be open to the surface of the part, or slightly sub-surface. Parts tested can be forgings, welds, castings, and stamped or machined ferromagnetic materials, such as steel and other alloys of iron, nickel, and cobalt.

Oil and water baths of 14A are normally used in horizontal magnetic bench units with integral magnetic field generators. With fluorescent magnetic particle suspensions, flaws generally appear more quickly in water than in oil baths, although water baths normally require anti-foam, corrosion inhibitors, and wetting agents. Remove 14A particles after inspection with an aqueous cleaning solution. When using a water bath process, an anti-corrosion solution is normally applied to the part after cleaning.

Benefits

- Clear, bright indications under ultra-violet light

- Can be suspended in water or petroleum distillate (oil) vehicle

- High sensitivity

- Excellent fluorescent contrast for